These special profile provide complete solutions in the configuration of every building, as well as ease in manufacturing.

-

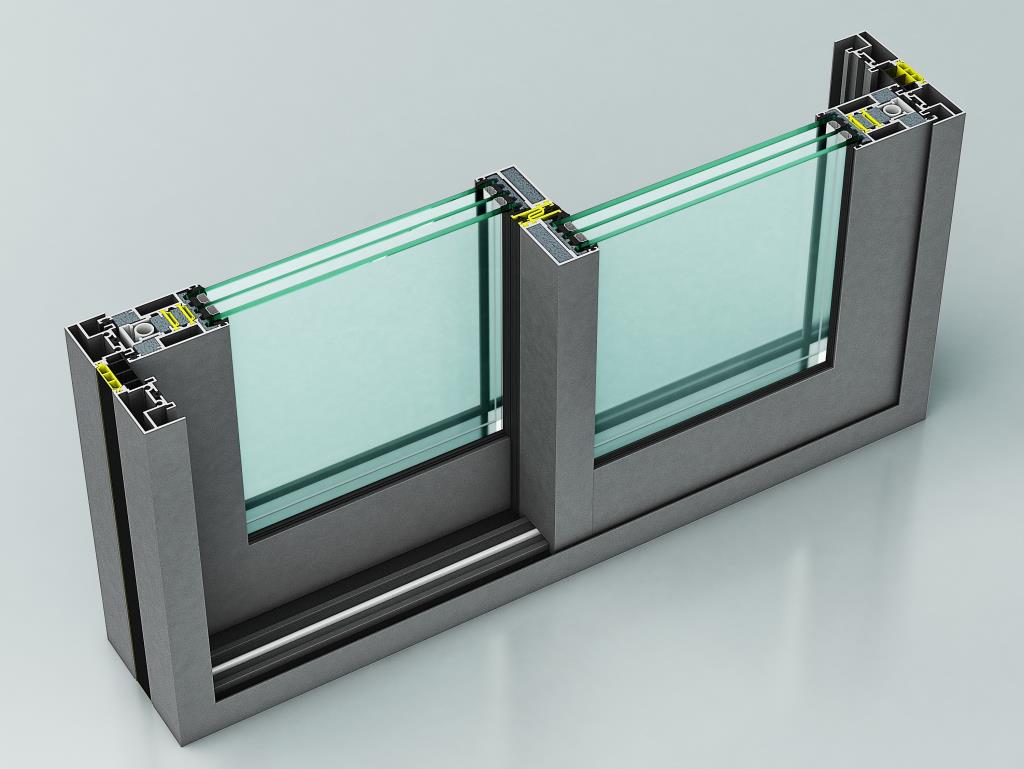

- It has lifting, then sliding mechanism.

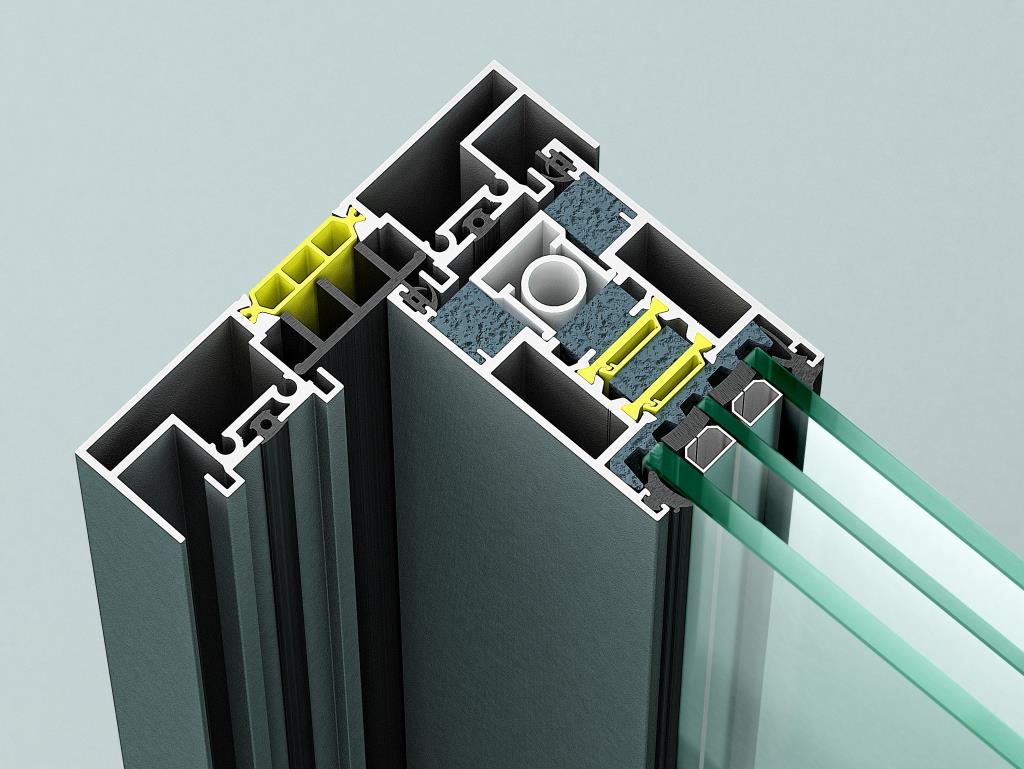

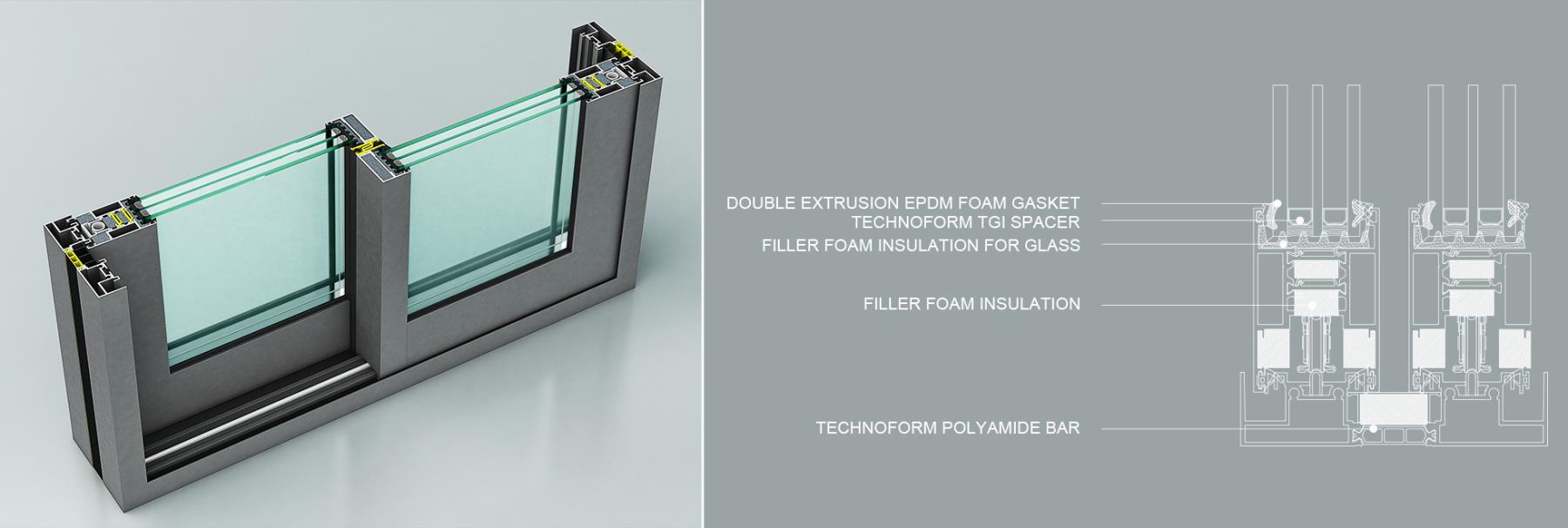

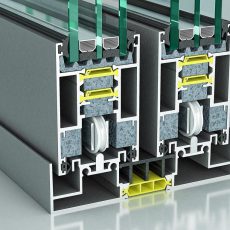

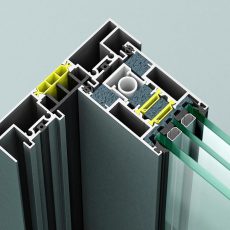

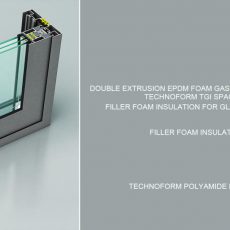

- It is a thermal insulating system with an aluminum cross-section 2mm and 24mm polyamide insulation.

- The sash is built with two same sides, has two identical chambers unlike competing systems, and thus the sash thickness of 52mm has a strong rigidity ratio, and perfect behavior at high temperatures and dark colors, when the competitive sliding panels bent so not lockable at the midday hours.

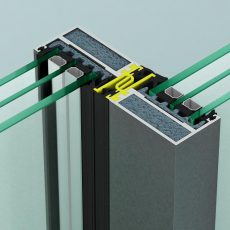

- At the same time, the intersection of the leaves sealed in rubber by EPDM and aluminum face is just 34mm!

- The face of leaf-sash splicing perimetrically remains the same and it is only 95mm, like the tilt & open AL39000 system.

- The guide is only 25mm when the competition is between 40 and 60mm.

- Sealing is achieved perimetrically with EPDM rubbers to which the lift & slide panel fits, thereby providing complete thermal break, as compared to simple sliding panels with brushes that have thermal losses. This property also gives them the opportunity to stabilize at any point of their movement when we turn down the handle.

- The equipment can be in 2-cost levels. The first form is lift & slide mechanism to minimize friction and leaf weight 200kg and the second form lift & slide mechanism for a weight of 300-400kg. The system can be developed two, three or four sash openings and combined harmoniously with the tilt & open AL39000 systems.

Ελληνικα

Ελληνικα